Timberland improves e-commerce production efficiency by a factor of 20

Timberland, a flagship brand under the VF Corporation, is known for its iconic outdoor footwear. While 5 of VF’s brands are taking advantage of dipp’s platform, one truly stands out for its ability to maximize efficiency when it comes to visual production for its e-commerce operations.

In the Taiwan market, Timberland offers over 1,000 products, requiring a robust system for consistent visual production. With a small team of 3 designers from the enabling agency - 91APP, Timberland faced the daunting task of launching, relaunching, or updating over 50 products each week.Every week, a team of 3 designers must launch, relaunch or update over 50 products.

However, by leveraging dipp’s creative automation, Timberland has scaled its operations, boosting efficiency by 20 times.

The challenge: Managing complex visual production for eCommerce

Before implementing dipp’s creative automation solution, Timberland’s production process involved managing a vast array of Photoshop files for each product and layout. With over 1,000 products to manage, this traditional method became incredibly cumbersome. The team faced:

- File management chaos: A separate Photoshop file for each product and layout type made tracking and updating assets incredibly difficult.

- Manual tasks: Product photography, smart objects copying, and pasting across product categories added significant manual effort.

- Limited efficiency: The team of designers was expected to churn out 50 product visuals every week—a task that was impressive but still not scalable.

The solution: Streamlining eCommerce production with dipp

By partnering with dipp, Timberland was able to automate much of the manual labor involved in e-commerce visual production. Here's how the process was streamlined:

-

Identifying and consolidating patterns: dipp’s team analyzed Timberland’s existing visual designs and identified recurring patterns. The result? Consolidating several layouts into one efficient design template. This reduction in template complexity allowed the team to work faster and more accurately.

-

Simplified spreadsheet-to-image process: Instead of manually updating each image with product details, Timberland implemented dipp’s spreadsheet-to-image process. This simple and powerful tool allowed the team to upload spreadsheets with product details that automatically populated images, eliminating the need for designers to manually input data.

-

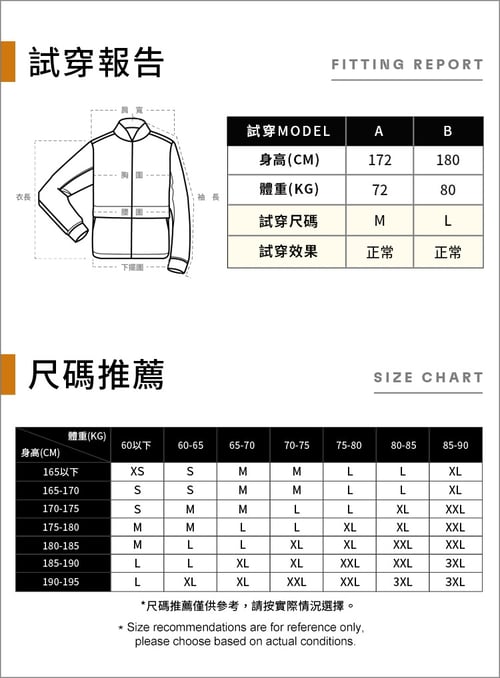

Automating image production: With dipp’s platform, Timberland was able to automatically generate product thumbnails, product description pages (PDPs), sizing charts, and more—everything was done in a fraction of the time.

-

Collaboration and scaling: By involving non-designer teammates in the process, Timberland reduced the designers’ workload by 3x. This enabled the team to focus on higher-level design tasks while automating the repetitive ones.

In the end we were able have set up a single set of design templates for all Timberland’s needs, like thumbnails, product description pages (PDPs), sizing charts, and other frequently used layouts. After showing the Timberland team around our platform, onboarding and setting some KPIs, the Timberland team got to work.

The results: 20x increase in eCommerce production efficiency

After adopting dipp’s platform, Timberland dramatically improved its eCommerce workflow efficiency. Here are the key results:

1. Boosted launch capacity: Timberland’s weekly product launches surged from 50 to over 1,000 in just one day, compared to the 7 days it used to take.

2. Faster time-to-market: With automated visuals, Timberland could launch products faster, meeting market demands in record time.

3. Streamlined workflows: Tasks like thumbnail creation, image cropping, and sizing charts, which previously took hours, were now automated, saving countless man-hours each week.

Examples:

Product thumbnails with model photography and all required logos and labels are automatically populated via a spreadsheet.

Product description images (lorikeets as they are called on Lazada) are automatically cropped according to guides and layout rules.

Sizing charts including technical drawings of items can also be automated using a spreadsheet.

Conclusion: Achieving 20x efficiency with dipp’s solutions

Now a year and 3 additional VF Corporation brands later, the process has become standardized and scalable not only for the brands mentioned but for all brands managed by 91APP. Timberland seeing a 20 times improvement in their overall creative operational efficiency is not simply because of dipp’s platform. There is a good deal of production process adjustments as well as organizational changes that must take place before introducing the platform as part of the process.

Contact us, to get your customized e-commerce workflow optimization plan.